Next step inU.S. Wind FeederSolution

Posted on 01/04/2021 at 16:45

Innovating for the feedering of next gen WTGs

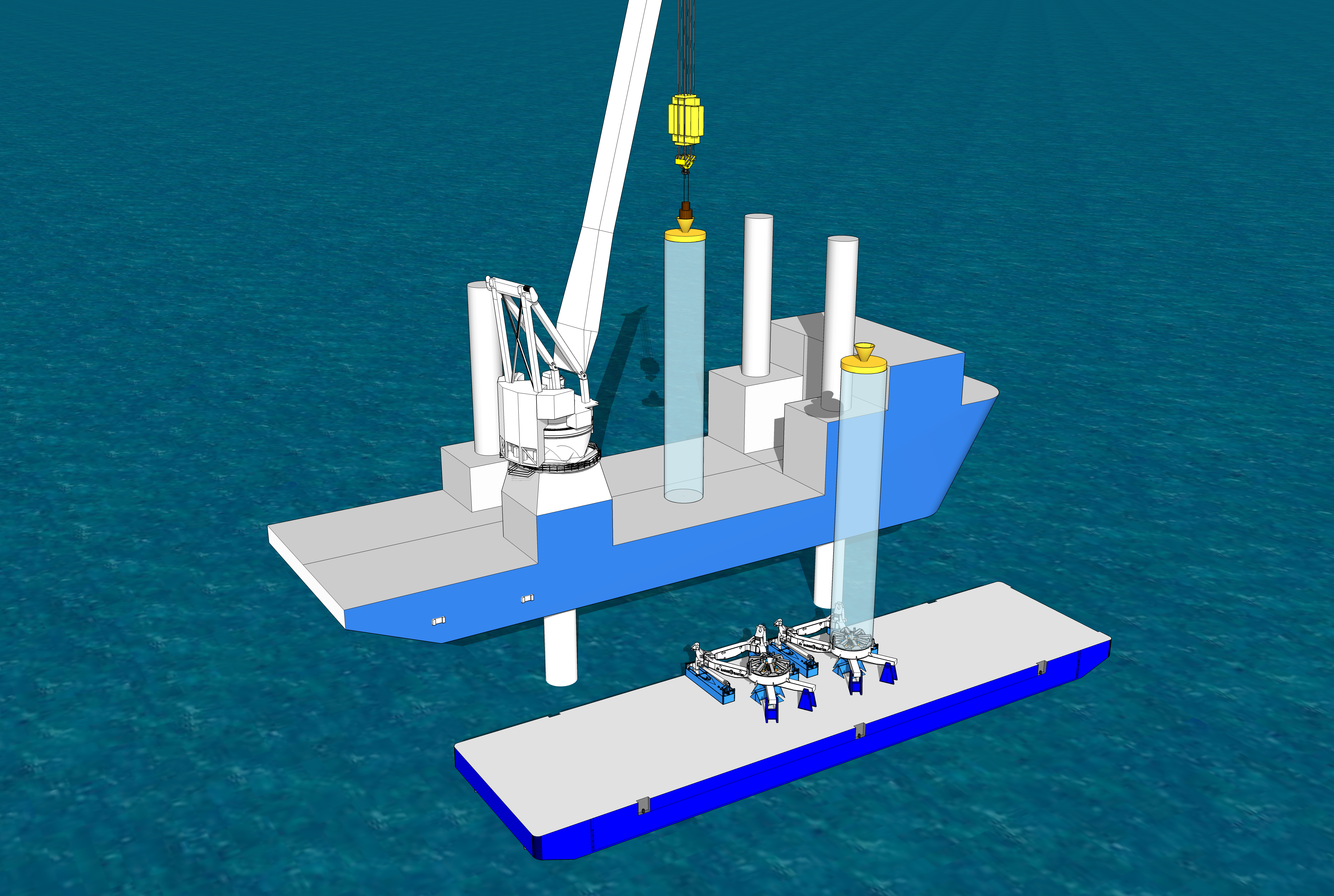

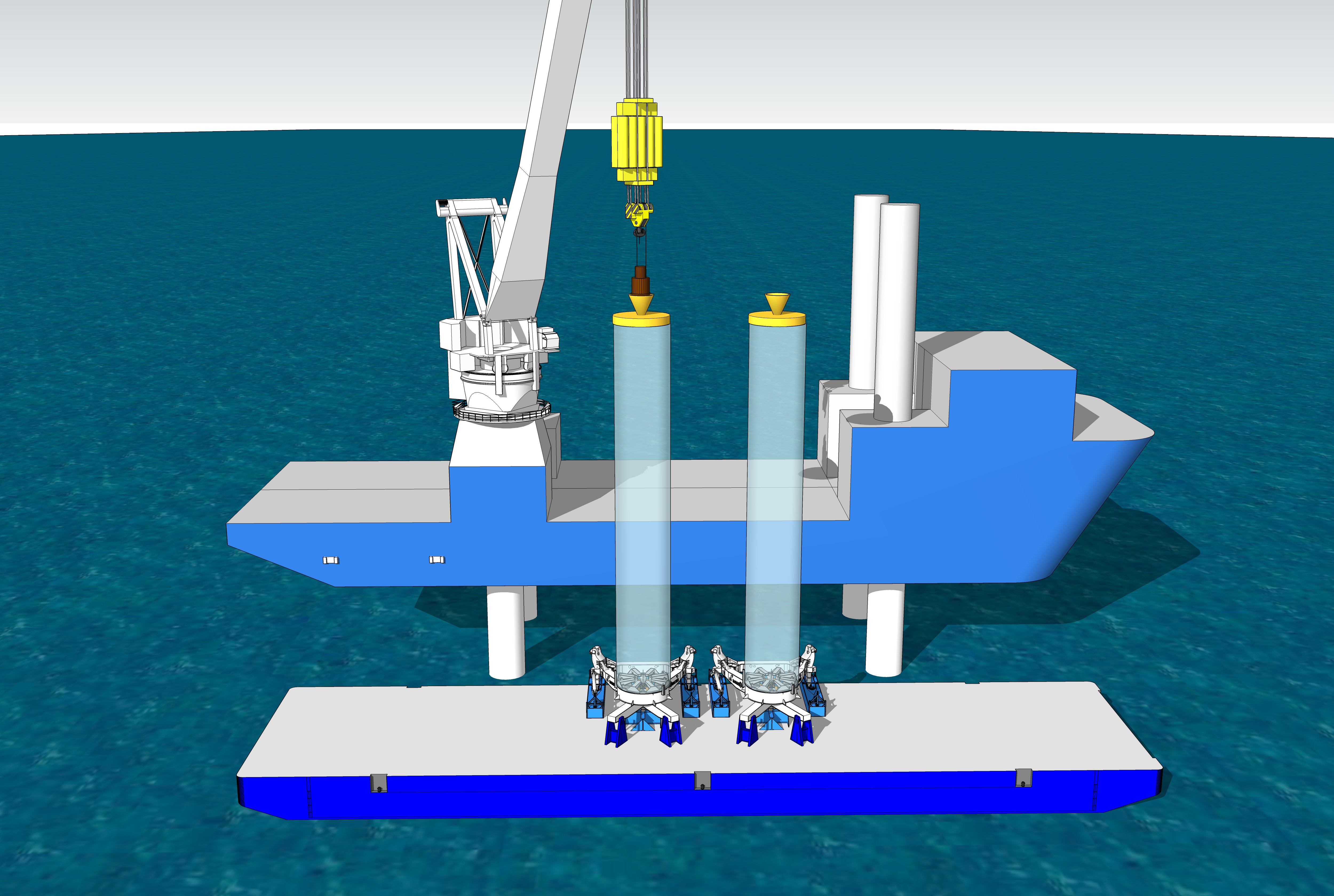

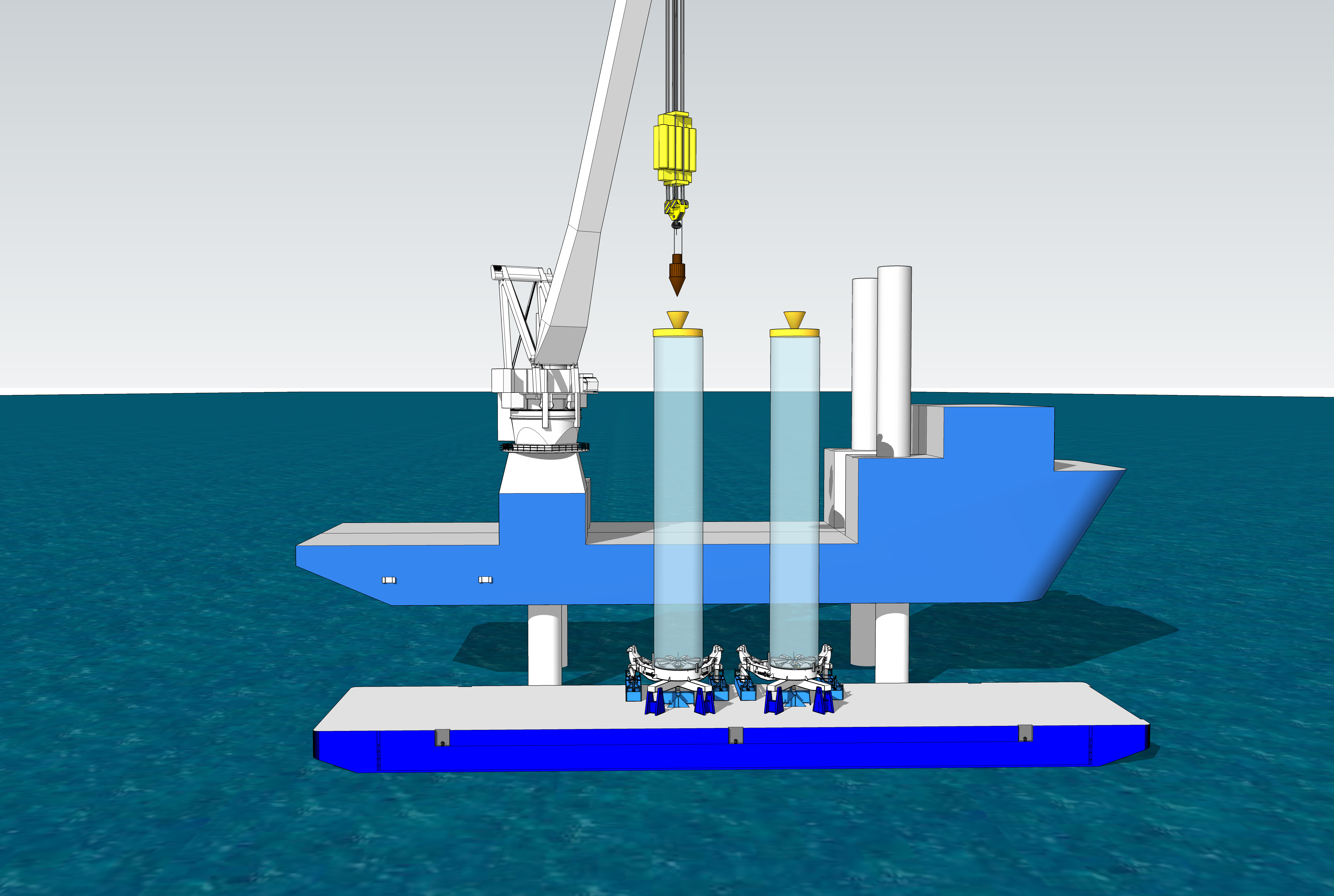

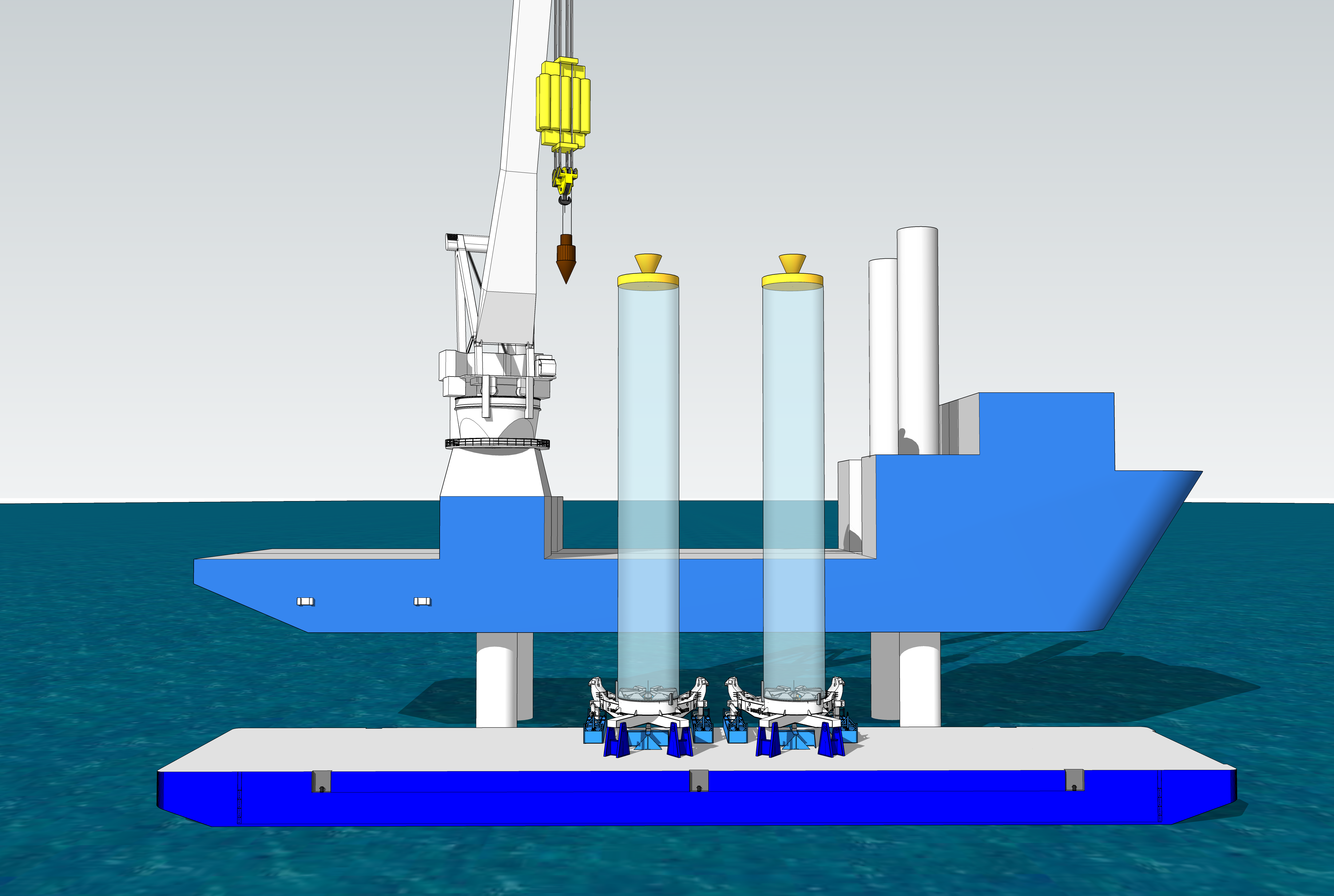

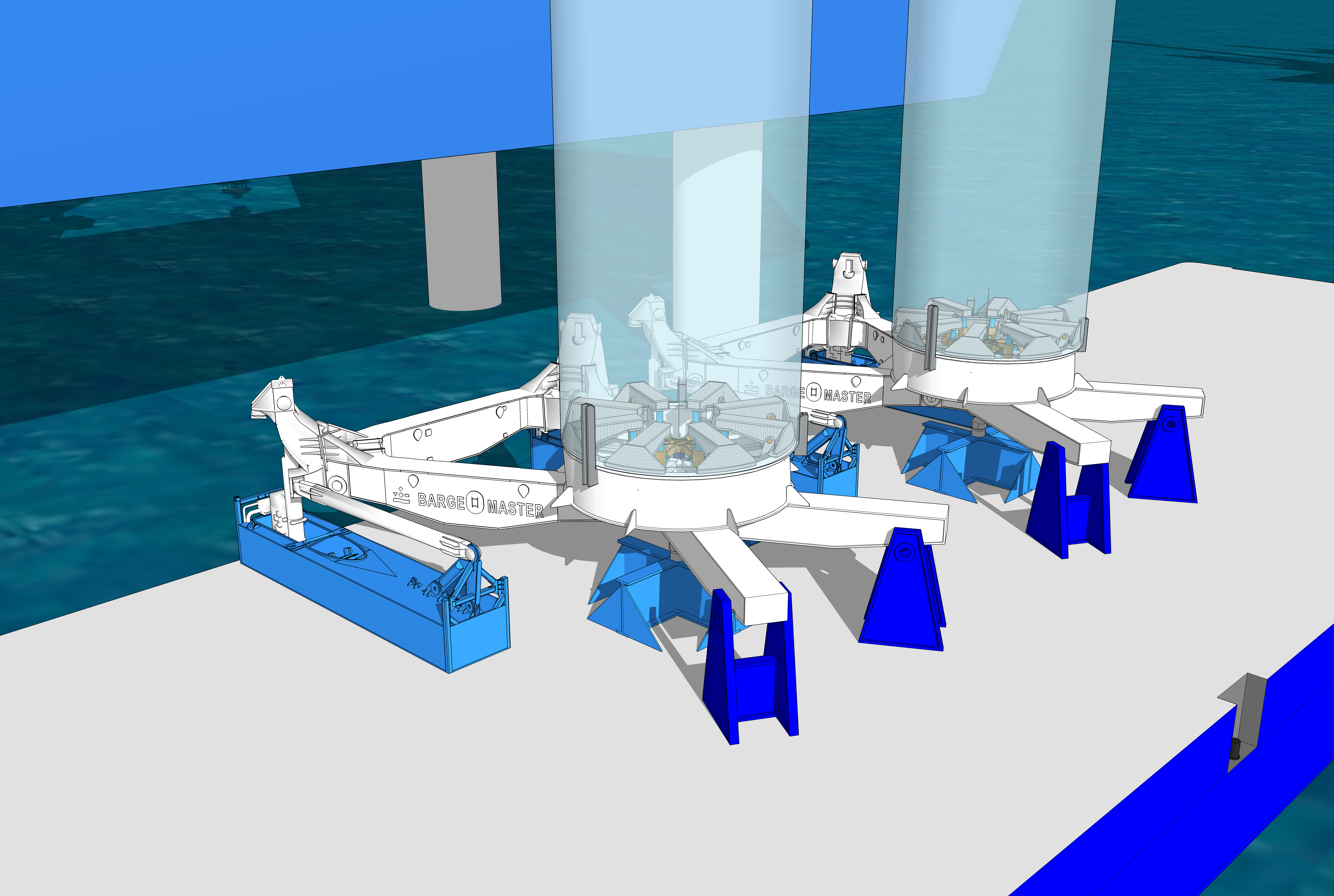

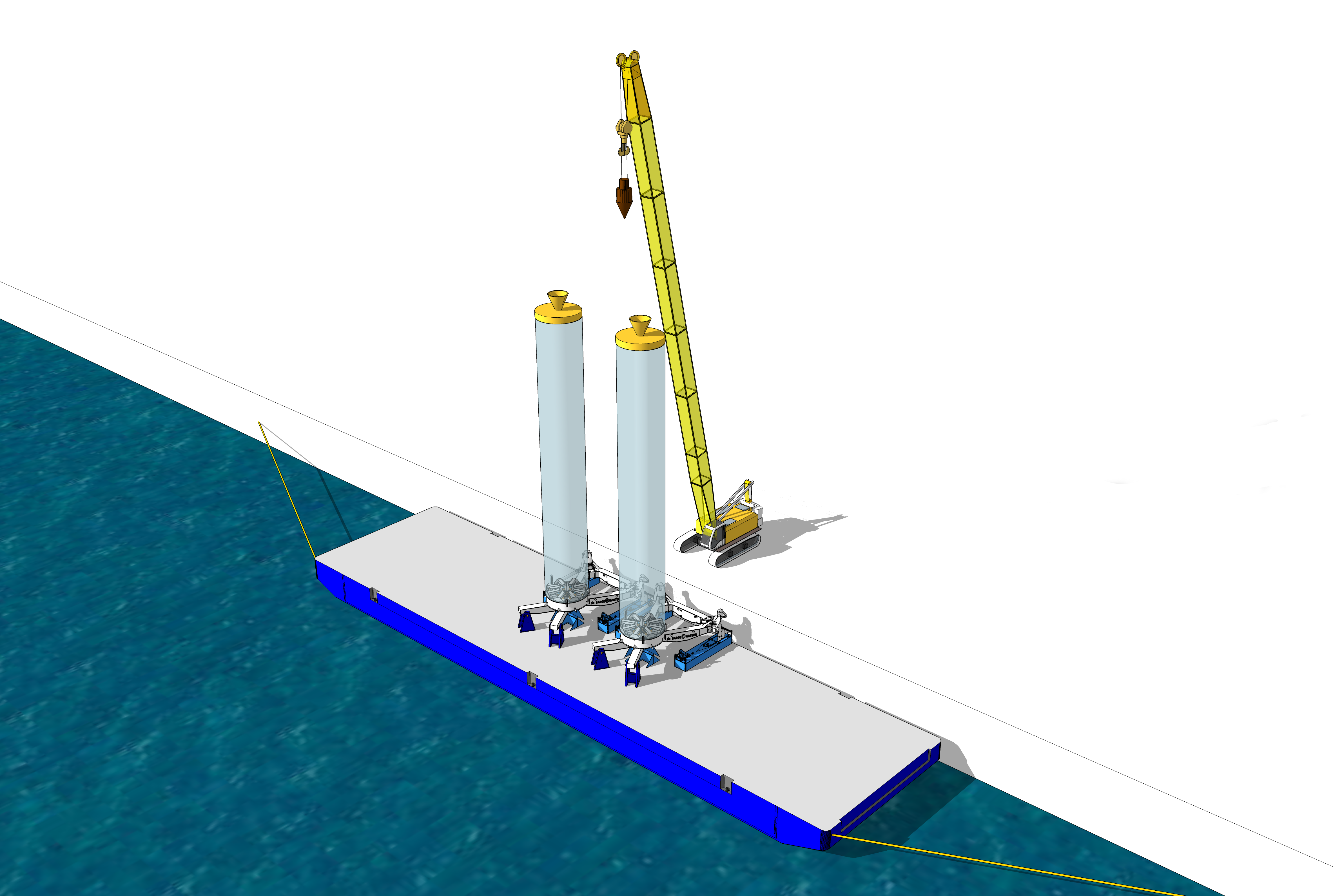

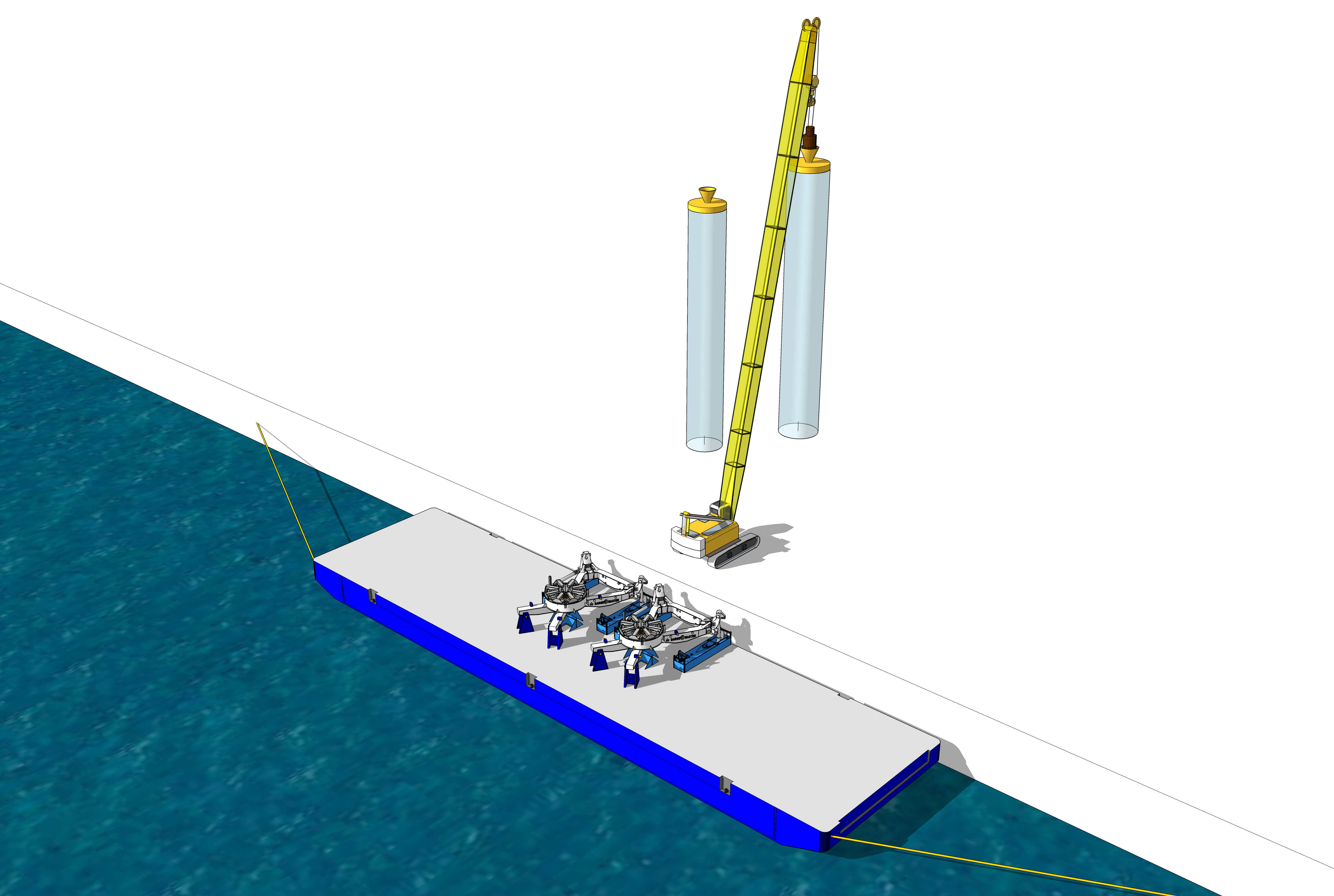

Barge Master has increased the capacity of its motion compensated platform to make it ready for feedering the next generation WTG’s.

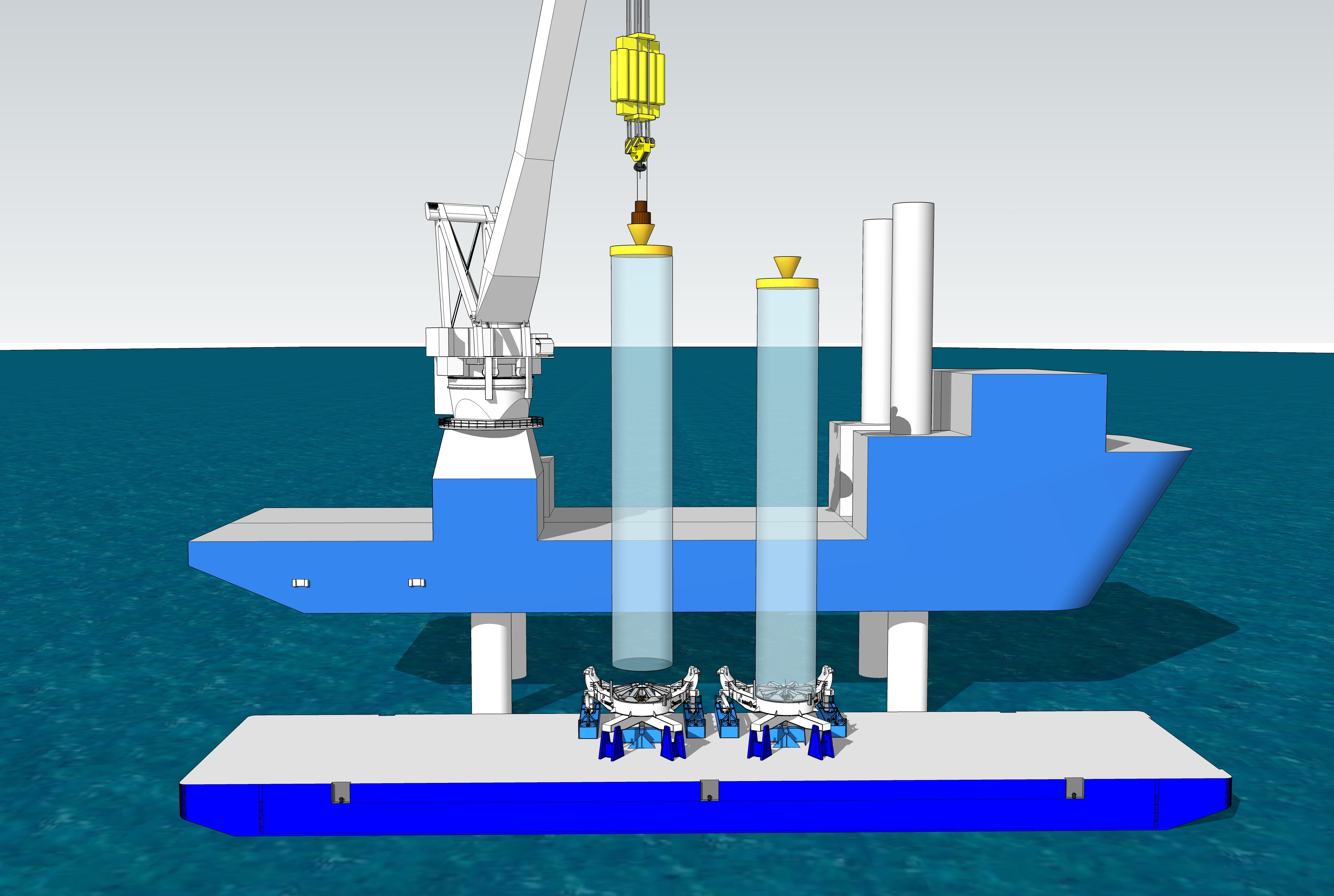

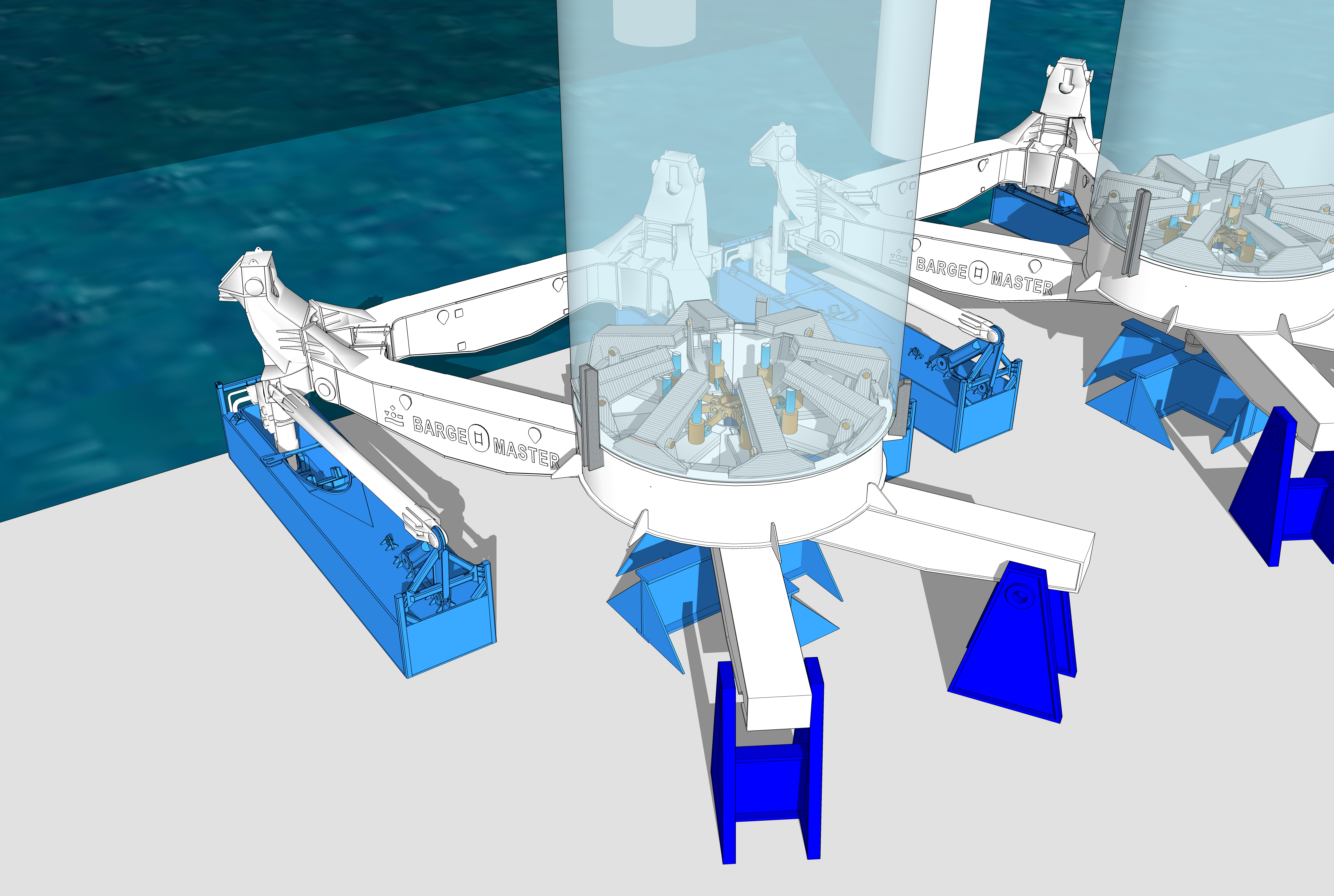

With the increased capacity of 800 ton load we keep the new tower sections with a high weight and Centre of Gravity (CoG) completely stable.

The Barge Master T700 compensates at the base of the tower sections for roll and pitch movements where a heave compensation solution in the hook assist in elimination of the heave motions.

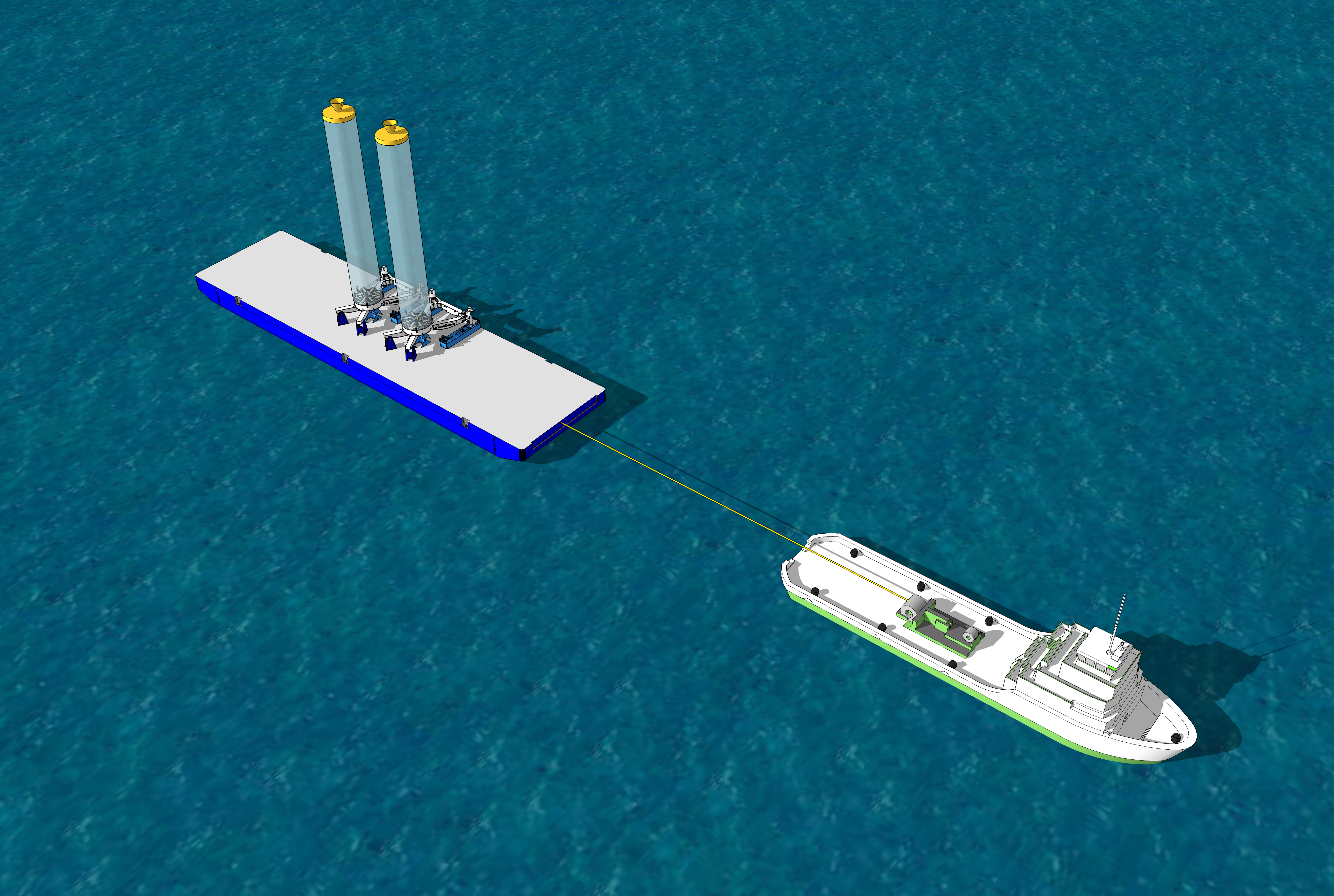

The motion compensated platform can be mobilized on any U.S. flagged vessel or barge, making it a Jones Act compliant solution.

The T700 can operate in sea states of over Hs 2.0 meters and will provide an increased workability of 40-60% more uptime during the installation of the turbines.

The motion compensated platform makes your operation safer and very cost efficient